CHAPTER 10- EXTENDING THE ORGANIZATION-SUPPLY CHAIN MANAGEMENT

Supply Chain Management

The average company spends nearly half of every dollar that it earns on production

In the past, companies focused primarily on manufacturing and quality improvements to influence their supply chains

Basics of Supply Chain

The supply chain has three main links:

- Materials flow from suppliers and their “upstream” suppliers at all levels

- Transformation of materials into semifinished and finished products through the organization’s own production process

- Distribution of products to customers and their “downstream” customers at all levels

Information Technology’s Role in the Supply Chain

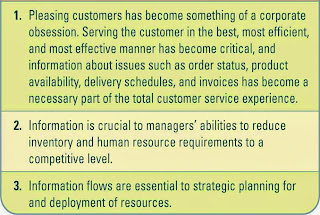

IT’s primary role is to create integrations or tight process and information linkages between functions within a firm

Factors driving SCM

Visibility

Supply chain visibility – the ability to view all areas up and down the supply chain

Bullwhip effect – occurs when distorted product demand information passes from one entity to the next throughout the supply chain

Consumer Behavior

Companies can respond faster and more effectively to consumer demands through supply chain enhances

Demand planning software – generates demand forecasts using statistical tools and forecasting techniques

Competition

Supply chain planning (SCP) software– uses advanced mathematical algorithms to improve the flow and efficiency of the supply chain

Supply chain execution (SCE) software – automates the different steps and stages of the supply chain

Speed

To succeed in today’s competitive markets, companies must align their supply chain with the demands of the markets they serve.

· Supply chain performance is now a distinct competitive advantage for companies proficient in the SCM area.

SCM Stories

· MAKE THE SALE TO SUPPLIERS

The hardest part of any SCM system is its complexity because a large part of the system extends beyond the company’s walls. Not only will the people in the organization need to change the way they work, but also the people from each supplier that is added to the network must change. Be sure suppliers are on board with the benefits that the SCM system will provide.

WEAN EMPLOYEES OFF TRADITIONAL BUSINESS PRACTICES

Operations people typically deal with phone calls, faxes and orders scrawled on paper and will most likely want to keep it that way. Unfortunately, an organization cannot disconnect the telephones and fax machines just because it is implementing a supply chain management system. If the organization cannot convince people that using the software will be worth their time, they will easily find ways to work around it, which will quickly decrease the changes of success for the SCM system.

ENSURE THE SCM SYSTEM SUPPORTS THE ORGANIZATION GOALS

It is important to select SCM software that gives organizations an advantage in the areas most crucial to their business success. If the organizational goals support highly efficient strategies, be sure the supply chain design has the same goals.

DEPLOY IN INCREMENTAL PHASE AND MEASURE AND COMMUNICATE SUCCESS

Design the development of the SCM system in incremental phases. For instance, instead of installing a complete supply chain management system across the company and all suppliers at once, start by getting it working with a few key suppliers, and then move on to the other suppliers. Along the way, make sure each step is adding value through improvements in the supply chain’s performance. While a big-picture perspective is vital to SCM success, the incremental approach means the SCM system should be implemented in digestible bites and also measured for success one step at a time.

BE FUTURE ORIENTED

The supply chain design must anticipate the future state of the business. Because the SCM system likely will last for many more years than originally planned, managers need to explore how flexible the systems will be when (not if) changes are required in the future. The key is to be certain that the software will meet future needs, not only current needs.

No comments:

Post a Comment